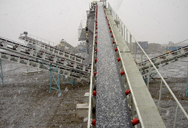

broyeur de pierres 10 m3 confiture de POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- stations de broyage giratoire de l usine de traitement du minerai machine

- Meulage de pierre cono washing

- liste des producteurs de moulin à billes

- sable prix fabricant

- indonesiacrushers coal mill

- concasseur de broyage petite

- le meilleur de concassage de roche des roches de granit

- machine Indonésie fabrication de sable zénith sweden

- apakah conique de broyeur a billes horizontal

- meuleuse de banc gxg6

- concassage broyage la page

- L'équipement de l'exploitation du sable de rivière aux EtatsUnis

- charbon concasseur 21 mm taille 1 kg de charbon de taille 6mm

- pdf tipos de Meulage de pierre de piedra

- iron ore agglomerates iron

broyeur pièces détachées et pièces en europe

Metals Special Issue : Iron Ore Agglomeration - MDPI

2023.2.28 Iron ore characteristics and their impacts on the final agglomerates’ quality and process performance; Evaluation technologies of iron ore for different agglomeration processes; Evaluation of agglomerates for blast furnace and alternative ironmaking

Read More

Iron Ore Agglomeration Technologies IntechOpen

2017.12.20 Sintering and pelletization are the most important agglomeration technologies, in this way, in the EU-27, 14 countries

Read More

(PDF) Iron Ore Agglomeration Technologies

2018.7.11 Iron ore sintering is a pretreatment step of smelting that agglomerates the iron ore using surface melting of green pellets to

Read More

(PDF) The Role of Basicity in the Formation of the Structure

2021.12.17 The phase composition (XRD) of iron ore agglomerates and their microstructure were analyzed by optical microscopy. Various dependences of influence

Read More

Agglomeration of Iron Ores Ram Pravesh Bhagat Taylor

2019.7.31 ABSTRACT. This book focuses on agglomeration, or the size enlargement process, of iron ores. This process sits at the interface of mineral processing and

Read More

Evolution behavior and mechanism of iron carbon agglomerates

2023.2.16 Iron carbon agglomerates (ICA) are the composite burden for low-carbon blast furnace (BF) ironmaking. In order to optimize the reactivity of ICA according to the

Read More

Strength of iron-ore agglomerates during reduction

1974.9.1 The iron-oxide material in the agglomerates consists of iron ore -- hematite and/or magnetite -- which in various forms is reduced to iron. The reduction usually takes

Read More

Analysis of a compact iron ore sintering process based on

2020.5.1 Analysis of a compact iron ore sintering process based on agglomerated biochar and gaseous fuels using a 3D multiphase multicomponent mathematical model

Read More

Review of organic binders for iron ore concentrate agglomeration

2014.5.1 This manuscript reviews organic materials that have been used to make iron ore concentrate pellets. Included are discussions on the development of organic binders,

Read More

Review Research in the Reduction of Iron Ore

Research in the Reduction of Iron Ore Agglomerates Including Coal and C-containing Dust Heinrich Wilhelm GUDENAU, Dieter SENK, Shaowen WANG, Karla DE MELO

Read More

Registration Dossier - ECHA

Iron ores, agglomerates. EC number: 265-996-3 CAS number: 65996-65-8 The product of agglomerating iron ore fines, concentrates, iron sinter, and other iron-bearing materials. Includes pellets, nodules and briquettes.

Read More

[PDF] Iron Ore Agglomeration Technologies Semantic Scholar

2017.12.20 Iron Ore Agglomeration Technologies. D. Fernández-González, J. Piñuela-Noval, Luis FelipeVerdeja. Published in Iron Ores and Iron Oxide 20 December 2017. Materials Science, Engineering. Iron Ores and Iron Oxide Materials. Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had

Read More

Effect of Iron Oxide Coatings on Thermal Conductivity of

2022.2.5 Engineering properties of soils coated with naturally occurring or artificially manufactured particles can significantly differ from those of uncoated soils. This study aims at evaluating the effect of iron oxide coatings on the thermal conductivity of silica sands. Laboratory thermal needle probe tests were conducted on uncoated, goethite coated and

Read More

Recent Trends in Ironmaking Blast Furnace Technology to

2016.9.3 The short distance between close-packed fine iron ore and carbonaceous materials in the agglomerates ensures fast reduction reaction of iron oxide. Furthermore, carbon gasification reaction and iron ore reductions are mutually accelerated and occur at lower temperature due to the coupling effect (Dutta and Ghosh 1994; Kasai and Matsui

Read More

Effect of Iron Content on Thermal Conductivity of

2023.3.30 We have simultaneously measured thermal conductivity (λ) and thermal diffusivity (κ) for polycrystalline ferropericlase with different Fe contents (Fp 3, Fp 5, Fp 10, Fp 20, Fp 30 and Fp 50) up to 23 GPa and 1100 K by a pulse heating method.Experiment results reveals that even small amounts of Fe in ferropericlase can strongly reduce the

Read More

Research in the Reduction of Iron Ore Agglomerates Including Coal and

2005.1.1 Due to the high contents of iron, fuel (carbon, oils) and calcium, the high-fuel-content dusts are regarded as an alternative to solid fuels and fluxes during the iron ore sintering and it can be ...

Read More

Strength of iron-ore agglomerates during reduction

1974.9.1 The iron-ore agglomerates are normally tested in a reduction gas consisting of 35% CO, 5% CO2 and 60% N2 by volume at 1,000. Heating is done in a nitrogen atmosphere, after which the agglomerates are reduced isothermically for a certain length of time. A couple of the agglomerates are then compressed one at a time -- still at reduction ...

Read More

(PDF) The angle of repose and size segregation of iron ore

2017.7.1 The apparent density of iron ore gr anules fluctuated slightly within the range from 2.8 g/cm 3 to 3.2 g/cm 3 , varying with the specific mater ial properties of individual granule samples .

Read More

Agglomeration of Iron Ores - 1st Edition - Routledge

4 天之前 Agglomeration of Iron Ores covers in considerable detail both the sintering and pelletising of iron ore fines and concentrates that are generated along with lump ore in iron ore mines around the world, either naturally or after upgrading in a beneficiation process. The book is devoted to a detailed treatise of the sintering and pelletising of the raw

Read More

High resolution X-ray microtomography for the

2017.12.25 Comparing these values with values of similar iron agglomerates in the literature, some empirical correlations and analytical models, the results proved that CT-simulation is a valid approach for capturing the peculiar details of the real sinter porous structure, thus to predict thermal behavior with higher accuracy than the simplified ...

Read More

Vale makes headway on low-emission iron ore briquette

2023.5.3 Agglomerates for blast furnaces can be produced with ore grades lower than 65% Fe. Vale says it is working to increase its production of high-quality iron ore and expand its capacity to concentrate ore, which also raises the iron ore grade, enabling the company to meet demand from steelmakers for these products.

Read More

Agglomeration and Characterization of Nickel Concentrate

2020.7.6 The standardization applied to iron ore was followed. The best result of crushing strength was 98.52 daN/pellet. The agglomerates with approved crushing strength for use in electric furnaces were smelted to produce alloys containing nickel; the agglomerates were characterized by scanning electron microscopy.

Read More

US20220106664A1 - Process for the production of iron ore

Iron ore sintering converts ore fines, usually with particle size distributions between 0.15 mm and 6.3 mm, called sinter feed, into larger agglomerates, called sinter. Its granulometric range is between 5 mm and 25 mm of particle size, presenting physical, metallurgical, and permeability characteristics satisfactory for efficient blast furnace ...

Read More

Mechanism and Prevention of Agglomeration/Defluidization during ...

2017.12.20 The mechanisms of agglomeration and defluidization and fluidization characteristic of iron oxide particles were investigated based on the theory of surface diffusion, interface reaction, surface nano/microeffect, and phase transformation. Moreover, a mathematical model was developed to predict the high-temperature defluidization

Read More

Sustainability Free Full-Text The Direct Reduction of Iron Ore with ...

2021.8.8 The steel industry represents about 7% of the world’s anthropogenic CO2 emissions due to the high use of fossil fuels. The CO2-lean direct reduction of iron ore with hydrogen is considered to offer a high potential to reduce CO2 emissions, and this direct reduction of Fe2O3 powder is investigated in this research. The H2 reduction reaction

Read More

Using Iron Ore Ultra-Fines for Hydrogen-Based Fluidized Bed

2022.6.1 This mathematical evaluation focuses on iron ore ultra-fines for their use in a novel hydrogen-based fluidized bed direct reduction process. The benefits of such a process include reduced CO 2 emissions and energy consumption per ton of product, lower operational and capital expenditure, and a higher oxide yield. Typical samples of iron ore

Read More

Quantitative Evaluation of Reaction Mode and Reduction

on the specified essential factors governing the reduction disintegration behavior of the iron ore agglomerates, i.e., iron ore sinters and pellets. Reduction disintegration index (RDI) values were measured after the reduction of the agglomerate samples using the gas mixtures of CO–H 2–CO 2–N 2. The mineral textures of reduced samples were

Read More

(PDF) Iron Ore Agglomeration Technologies Provisional chapter Iron Ore ...

2018.7.11 Iron ore sintering is a pretreatment step of smelting that agglomerates the iron ore using surface melting of green pellets to improve the quality of the steel product. The sintering process not ...

Read More

Study on Mechanical Properties and Reduction Behavior of

2023.8.23 The mechanical stability of iron ore agglomerates was evaluated using various binder percentages prior to their reduction. The results of the mechanical stability tests are presented in Fig. 2. From the figure, it can be concluded that the mechanical stability of the iron ore agglomerates increases with increasing binder percentage.

Read More

Review and data evaluation for high-temperature

2023.8.27 layered-dense iron between 873 and 1023 K, and fibrous iron between 973 and 1273 K [16,18]. Hereby, it is expected that only porous magnetite and porous iron would form in the reduction at a high temperature above 1273 K. By the way, fibrous iron is well known for causing swelling of iron ore pellets [19] and sticking of particles [20]. The ...

Read More

MECHANISMS OF REDUCTION OF IRON ORE/COAL AGGLOMERATES

Laboratory studies of chemical kinetics and heat transfer in the reduction of iron ore/carbon (coal) mixtures in various forms are reviewed. Therefore, the rate-limiting steps, which are of critical importance in process development, may be identified or suggested for a given set of conditions. Commercial operations using rotary hearth furnace (RHF) for the reduction of

Read More

(PDF) Using of Adhesives and Binders for

2022.5.11 iron ore agglomerates with use of sodium silicate . containing binder. Akzo Nobel Inc. 2007, US Pat-ent 2007/0119563 A1. 31. ... from iron-ore concentrate made at the Sokolovsko-

Read More

Effect of Added Olivine on Iron Ore Agglomerate During

2017.12.23 The effect of titanium oxide on iron ore agglomerates is studied by the use of test sinter, test pellets and synthetic briquettes under laboratory conditions. Titanium favours secondary hematite ...

Read More

Inside Vale’s green briquette megahubs and how they will work

2023.5.11 “Vale’s green briquettes are produced with very flexible and low-carbon technology. Since it is an agglomerate from iron ore fines, the resulting direct-charge material has all the necessary attributes to be used directly in conventional, mature and existing ironmaking reactors such as blast furnaces and direct- reduction furnaces,”

Read More

Biochars in iron and steel industries - ScienceDirect

2019.1.1 During blast furnace ironmaking, partial substitution with biochars can be used for sintering iron ore, carbon composite agglomerates, and as an auxiliary fuel injectant in the tuyères. Biochars also find application as charge carbon and slag foaming agent in electric arc furnace steelmaking. While some of these technologies are still under ...

Read More

Magnetochemistry Free Full-Text A Study of the Structure

2023.9.22 The iron ore and titanomagnetite agglomerates obtained under industrial conditions were tested. Table 6 shows the values of the thermo-mechanical strength LTD +6.3 (fraction +6.3 mm). The results shown in Figure 11 indicate that the strength of the agglomerates has different values, not exceeding 45%. After low-temperature sintering,

Read More

Global Iron Ore Market Report 2022: Major Players Include

2023.2.20 The global iron ore mining market is expected to grow from $166.94 billion in 2021 to $188.69 billion in 2022 at a compound annual growth rate (CAGR) of 13.0%. The iron ore mining market is ...

Read More

Metals Free Full-Text The Effect of Concentrate/Iron Ore

2018.11.21 The work is focused on studying the influence of the ratio of concentrate to iron ore on the phase composition of the iron ore agglomerate. The concentrate has significantly higher iron content than used iron ore, and is a determining factor, which influences the richness of the batch and consequently, the richness of the agglomerate.

Read More

Agglomeration of Iron Ores Ram Pravesh Bhagat Taylor

This book focuses on agglomeration, or the size enlargement process, of iron ores. This process sits at the interface of mineral processing and extractive metallurgy. The book begins with a discussion of raw materials preparation and the beneficiation process. It then describes fundamental principles of the sintering and pelletization processes ...

Read More

高钙赤铁矿烧结的矿物特性、冶金性能及相结构演变 - USTB

2017.5.29 As the content of the Ca-rich iron ore increases, sinter agglomeration shifts from localized liquid-phase bonding to a combination of localized liquid-phase bonding and iron oxide crystal connection. Based on an examination of the greater weight value of productivity with grey correlation analysis, the Ca-rich iron ore is beneficial for the

Read More

>> Next:Vsi Limpact A Axe Vertical De Concassage