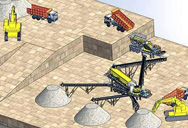

broyeur à boulets Grille Décharge POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- pour séparer le minerai d or

- sociétés minières au burkina fasso

- 1998 parker 1165 concasseur à machoires prix

- sops prosedure et le nettoyage de broyeur à boulets

- olx palackad broyeur de pierres

- de puissance pour broyeur de pierres

- rebelle concasseur a percussion

- animation de concasseur Indonésie machoires

- soupapes de décharge de lusine de charbon

- amenagement de station de concassage de ton heure

- broyeur de concasseur à vendre

- surface de calcaire liste de prix de Minner

- les technique de Tunisie de la raffinerie d'or

- fabricants de machines de concassage de pierre industrielle

- broyeur vertical d occasion à vendre

broyeur pièces détachées et pièces en europe

Broyeurs et épareuses d'occasion - Matériel agricole

Consultez nos annonces de broyeurs et épareuses d'occasion de particuliers et professionnels: broyeurs de branches, gyrobroyeurs, broyeurs forestiers...

Read More

Broyeur, épareuse d'occasion à vendre - France - Agriaffaires

Vous cherchez un Broyeur, épareuse d'occasion? Bienvenue sur Agriaffaires, leader de la petite annonce de matériel agricole.

Read More

Gyrobroyeur d'occasion - France - Agriaffaires

Vous êtes à la recherche d'un gyrobroyeur d'occasion à vendre ? Agriaffaires, propose 502 annonces de gyrobroyeurs d'occasion. Trouvez l'équipement que vous cherchez à un

Read More

Broyeur / Gyrobroyeur / Epareuse occasion à vendre - Mascus

Broyeur / Gyrobroyeur / Epareuse occasion à vendre - Mascus France Créez une annonce ! Des milliers d'annonces de matériel agricole broyeur / Gyrobroyeur / Epareuse

Read More

Broyeur à axe horizontal d'occasion à vendre - France

Broyeur, épareuse - autre. Vous cherchez un Broyeur à axe horizontal d'occasion? Bienvenue sur Agriaffaires, leader de la petite annonce de matériel agricole.

Read More

Gyrobroyeur d'occasion - Annonces Materiel Agricole

Gyrobroyeur d'occasion : consultez nos annonces gratuites Materiel Agricole de particuliers et professionnels sur leboncoin.

Read More

Broyeur industriel d'occasion à vendre - Osertech

6 天之前 Marque reconnues : Retsch, FrymaKoruma, Fitz-Patrick, Frewitt, Hosokawa, Poittemill Forplex, . Retrouvez la liste de nos annonces en stock : Broyeur industriel d'occasion. Sélection d'équipement industriel et

Read More

Broyeurs de branches d'occasion et neufs à vendre

Trouvez un Broyeur de branches parmi les 531 annonces de Broyeurs de branches. 531 annonces disponibles Broyeurs de branches d'occasion et neufs à vendre Broyeurs de

Read More

» Broyeuses d'occasion à vendre - Machineseeker

Broyeuses acheter d'occasion Top marques, offres enchères Acheter et vendre des machines d'occasion sur Machineseeker

Read More

broyeur à rouleaux vertical loesche

\n \n rouleau vertical broyeur loesche \n. rouleau vertical broyeur loesche.La technologie Loesche tojours avec une longueur d'avance Loesche est à l'origine de la technologie du broyage du clinker et du laitier de.Bavarder sur Internet.pre: coordonnées du broyeur sayaji next: les différents moulin à mélange et le coût loesche broyeur verticalBroyeurs

Read More

Broyeur de branches d'occasion à vendre , Belgique

Votre expérience sur notre site est une priorité. C’est pourquoi nous utilisons des cookies au titre de cet intérêt légitime à améliorer l’expérience utilisateur, réaliser des statistiques et vous proposer des offres publicitaires adaptées à vos centres d’intérêts dont, avec votre accord, celles à proximité.

Read More

broyeur - Jardin Terrasse 2ememain

221 annonces correspondant à 'broyeur Jardin Terrasse ... travail : 1,5 m. Pivote hydrauliquement de 0,5 m vers la droite. Nouveaux marteaux. Parfait état de fonctionnement. A vendre en raison d'achat d'un broyeur plus large. ... Terrasse location broyeur branche broyeur de branches occasion broyeur viking broyeur branches dans

Read More

manuel de broyeur cru vertical en format pdf

\n \n broyeur machine.pdf \n. broyeur a boulets modes de defaillance pdf.broyeur à boulets conception de la machine pdf Le broyeur à boulets conception type de fichier pdf.manuel de maintenance broyeur «.Manuel Instruction BROYEUR BG 65et compris les instructions de cette notice.N'utiliser le broyeur de résidus pour aucune autre application que celle

Read More

Gyrobroyeur Desvoys d'occasion à vendre - France

Gyrobroyeur Desvoys d'occasion à vendre - France. Annuaire des fournisseurs. Observatoire des prix. Broyeur, épareuse. Broyeur, épareuse. Broyeur à axe horizontal. Broyeur d'accotement. Broyeur forestier. Broyeur de pierres.

Read More

Gyrobroyeur FRANCE, 5 annonces de Gyrobroyeur FRANCE d'occasion

Gyrobroyeur FRANCE occasion, 5 annonces de Gyrobroyeur FRANCE d'occasion en vente sur Europe Agri - le site dédié à l'achat de FRANCE d'occasion. ... Europe-Agri, le site spécialisé pour vendre vos matériels de agricole d'occasion. Les autres sites du groupe : Europe-Camions: Achat vente de camion occasion; Europe ...

Read More

Gyrobroyeur d'occasion à vendre - France - Agriaffaires

Votre expérience sur notre site est une priorité. C’est pourquoi nous utilisons des cookies au titre de cet intérêt légitime à améliorer l’expérience utilisateur, réaliser des statistiques et vous proposer des offres publicitaires adaptées à vos centres d’intérêts dont, avec votre accord, celles à proximité.

Read More

Travail du sol d'occasion à vendre - France - Agriaffaires

Broyeur à sarments Pièce détachée Matériel viticole - autre Voir moins. Travail du sol d'occasion à vendre . 420 Annonces . Trier. Trier par; Distance Distance Prix marchand HT Prix marchand HT Prix HT Prix HT Prix HT location par jour ...

Read More

broyeur à boulets horizontal vs vertical mill

\n \n Rechercher les fabricants des Machine Broyeur Planétaire. \n. Balance de laboratoire Broyeur À Boulets Planétaire Horizontal Rectifieuse pour la Fabrication De Poudre.Broyeur À Boulets Planétaire Vertical Machine Pour MineralChemicalFood Broyage de Poudre.3884 planetary ball mill machine sont disponibles sur.Environ 10% sont des équipements de

Read More

Broyeur / Gyrobroyeur / Epareuse occasion à vendre - Mascus

Voici une liste complète de matériel agricole d’occasion à vendre sur Mascus, dans de nombreuses marques et leurs multiples modèles, ainsi que leurs pièces détachées ou pièces de rechange. ... Le broyeur à axe vertical est couramment utilisé par les agriculteurs et les professionnels des espaces verts. À lames ou à chaînes, il ...

Read More

Broyeur forestier occasion, 76 annonces de Broyeur forestier, d ...

Broyeur forestier occasion, 76 annonces de Broyeur forestier à vendre sur Maroc Agri - Achat de , trouvez votre Broyeur forestier d'occasion parmi un...

Read More

Broyeur, épareuse - autre d'occasion à vendre - France

Vous cherchez un Broyeur, épareuse - autre d'occasion? Bienvenue sur Agriaffaires, leader de la petite annonce de matériel agricole. ... autre d'occasion à vendre . 265 Annonces . Trier. ... VENTE POUR LE COMPTE D'UN CLIENT Broyeur à axe vertical avec roue libre Largeur de broyage 1m80 Boîtier 120 CV Attelage 3 point Kit chaîne Patins ...

Read More

broyeur in All Categories in Québec - Kijiji Canada

HOC STG13 HONDA BROYEUR DE SOUCHES 13 HP + GARANTIE DE 2 ANS + LIVRAISON GRATUITE À L'ÉCHELLE DU CANADA. Québec. FINANCEMENT DISPONIBLE - 1 (844)440-4014 - WWW.HOCANADA.COM Broyeur de souches STG13 Honda 13 CV La rectifieuse Honda Stump STG13 est dotée d'un nouveau système de

Read More

Broyeur, épareuse Desvoys d'occasion à vendre - France

Vous cherchez un Broyeur, épareuse Desvoys d'occasion? Bienvenue sur Agriaffaires, leader de la petite annonce de matériel agricole. Votre expérience sur notre site est une priorité. C’est pourquoi nous utilisons des cookies au titre de cet intérêt légitime à améliorer l’expérience utilisateur, réaliser des statistiques et vous ...

Read More

Broyeur de branches d'occasion à vendre , France - Agriaffaires

Broyeur de branches d'occasion à vendre , France. Broyeur à axe horizontal. Broyeur d'accotement. Broyeur forestier. Broyeur de pierres. Broyeur de pommes de terre. Broyeur, épareuse - autre. Auvergne-Rhône-Alpes. Bourgogne-Franche-Comté.

Read More

Broyeur industriel d'occasion à vendre - Osertech

6 天之前 Accueil > Machines industrielles disponibles > Broyeur industriel. Retrouvez ici la liste de toutes nos annonces : Broyeur industriel d’occasion. Osertech référence une sélection d’équipements et de matériel de seconde main disponibles, dans ses locaux et ceux de ses partenaires, pour vous permettre de trouver les meilleures opportunités.

Read More

importance reducteur de broyeur vertical du ciment

\n \n reducteur broyeur grupoembalajes \n. reducteur de broyeur vertical.importance r#233ducteur de broyeur vertical du ciment broyeur a fleauxgtgtSolutions.R#233ducteurs R#233ducteur de vitesse (8) pi#232ces de.fonctionnement de broyeurs #224 ciment vertical broyeur vertical de broyage de

Read More

GitHub

machine verticale de broyeur d impacteur d axe. Concasseur Centrifuge d'Axe Vertical à Rotor Profond de. Le concasseur Centrifuge d'Axe Vertical à Rotor Profond de Série B est

Read More

fr/broyeurs à percussion à arbre vertical occasion en

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

» Tours verticaux d'occasion à vendre - Machineseeker

Tours verticaux d'occasion à vendre ... à l'état neuf (d'occasion), TOUR VERTICAL OKUMA HOWA CARACTÉRISTIQUES TECHNIQUES Fabricant Okuma Modèle V60R CNC Fanuc 18i-TB Diamètre de tournage max. 700 mm Tournage 1000 mm ... 30kW Index de la broche du broyeur : 5º clamp FEEDRATE Avance rapide (axes X, Y, Z) : 40.000 mm/min.

Read More

Concasseurs / broyeurs fixes d'occasion et neufs à vendre ,

Trouvez un Concasseur / broyeur fixe parmi les 78 annonces de Concasseurs / broyeurs fixes. 78 annonces disponibles Concasseurs / broyeurs fixes d'occasion et neufs à vendre Concasseurs / broyeurs fixes d'occasion et neufs à vendre , France ... à axe vertical 3. à barres 1. à mâchoires 20. à percussion 21.

Read More

vitesse du broyeur à rouleaux vertical

\n \n Boîte de vitesse verticale Loesche Lm de moulin \n. moulins occasion de rouleaux anneau vertical.moulin 5e balle de vitesse de meulage anneau moulin.avantages d'un broyeur vertical à rouleaux..house de molino vertical loesche.loesche vertical mill lm 56.3.le moulin de broyage vertical de srie.vertical de rodillos lm 56.4 para la.construit sur mesure

Read More

fr/capacité du broyeur vertical 15tph d occasion.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

fr/broyeurs à ciment d occasion à vendre.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/petit broyeur vertical à vendre.md at main ziyoujudian/fr

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

» Mise au rebut / recyclage d'occasion à vendre

Mise au rebut / recyclage d'occasion à vendre (2 312) CATÉGORIES POPULAIRES. Machines de criblage . 394 ... Acier inoxydable Broyeur à billes vertical : check Dimensions du boîtier : dia. 320x900mm Entrée : dia. 35mm Sortie : dia. 35mm Moteur : 55 kW 380/690 Volt Avec interrupteur : check Poids : 2650 Kg Encombrement : 2,1x1,5 M Hauteur ...

Read More

concasseur rotatif axe vertical prab occasion à vendre

\n \n axe horizontal prix de concasseur \n. Concasseur Axe Vertical Sbm aimad.ball mill starway Équipements de concassage,broyeur broyeur a sable Axe Vertical mi 2100 Concasseur de.broyeur ¨¤ >» Obtenez Prix fabricant broyeur axe horizontal SBM Get Price » Achat concasseur à percussion à arbre vertical à Glarus.Broyeur à axe horizontal

Read More

fr/broyeur à rouleaux vertical à vendre.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

GitHub

broyeur vertical d occasion. Broyeur à axe horizontal d'occasion en vente sur Marsaleix. Retrouvez 16 broyeur à axe horizontal d'occasion en vente sur Marsaleix.Recherchez votre

Read More